M&M Piston Valves for Autoclaves for Food Sterilisation

Autoclaves for Food Sterilisation

|

A very common steam application where the M&M piston valve is used is in machines for food sterilisation.

These machines are called Autoclaves.

|

Food processing obtained through sterilisation consists of:

– Steam cooking of food raw materials such as sauces, jams or marmalade;

– The packaging of fresh food into jars, bottles, cans or packets with superheated steam.

Through heat sterilisation, all micro-organisms dangerous to human health are completely destroyed without toxic residues on foodstuff. |

PLANT DESIGN

|

APPLICATION

|

Media: Air

Pressure: Atmospheric

Temperature: 25° C

Seal Material: PTFE |

|

PAV – D

Media: Water

Pressure: Atmospheric

Temperature: 70° C

Seal Material: PTFE

|

|

PAV – A & B

Media: Vacuum

Pressure: -1 bar

Temperature: 25° C

Seal Material: PTFE |

|

PAV – C

Media: Steam

Pressure: 2 bar

Temperature: 121° C

Cycle: 10 – 15 min.

Seal Material: PTFE

|

|

|

1st Stage – Vacuum

Product placed in a sterilizer is closed inside the autoclave. Before starting sterilisation, valves (A)(B) create a –1 bar depression inside the chamber through a vacuum pump. Vacuum is needed to prevent air sacs at not controlled temperatures from creating, which are potentially dangerous to the quality of sterilisation.

2nd Stage – Sterilisation

During the sterilisation cycle valve (C) controls steams at 121ºC temperature and 2 bar pressure for a processing time of 10-15 minutes.

3rd stage – Exhaust

Once the sterilisation cycle is over, valve (C) closes, valve (D) opens restoring the atmospheric pressure, valves (E)(F) empty water created through steam condensation at 70°C temperature and atmospheric pressure. The port can then be opened to take out processed products.

|

The M&M PAV is an ideal valve to use in this application. The valve is fast acting on both air and spring, its durable design provides a reliable and long service, it is also fully repairable/serviceable. The PTFE seals are suitable for temperatures up to 180 degrees C and due to the compact actuator size, it uses a very low air consumption, requiring relatively small air pressures to operate.

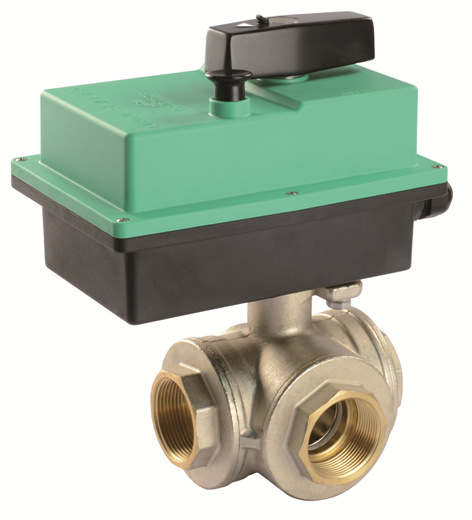

Bi-directional Normally Closed Bronze or Stainless Steel PAV

Ø 63 Actuator – 1/2”gas Connection

Medium Direction over/under seat

Piloting Pressure min. 5,5 bar over seat

Piloting Pressure min. 3,8 bar under seat

Piloting Pressure max 10 bar

Working Pressure 0-16 bar

Seal Material PTFE

|

|

If you require a valve for controlling steam please contact our technical office to discuss your requirements.

01234 855888

or email sales@v-flowsolutions.co.uk