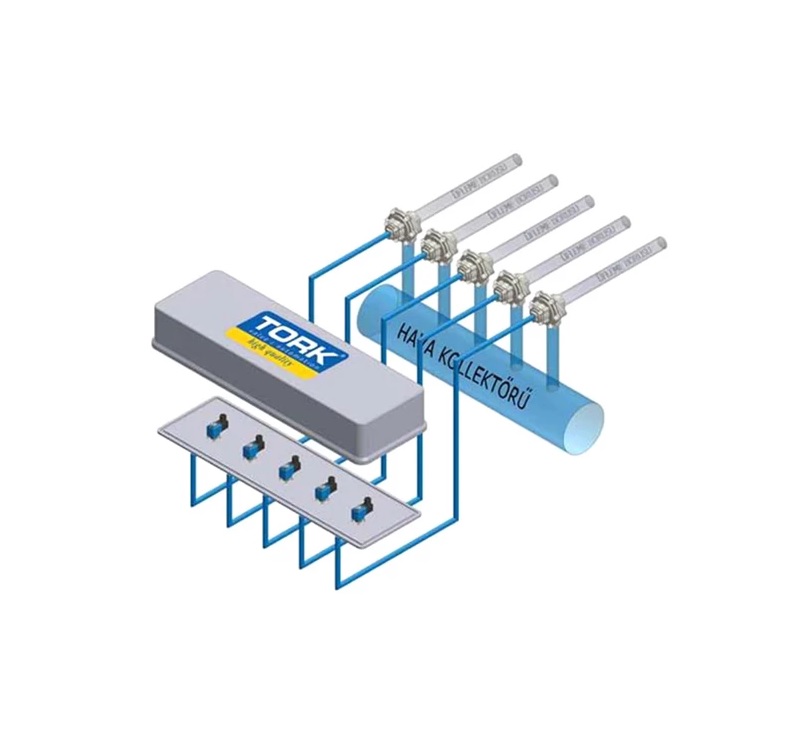

Dust Collector Pulse Valves

Pulse Solenoid Valves are generally used in cement, ceramics, paint, feed thermal power plants, concrete plants, detergent, glass, and iron and steel industry to shake off the dust accumulated in bag filters or to prevent the solidification of the dust accumulated in the bunkers.

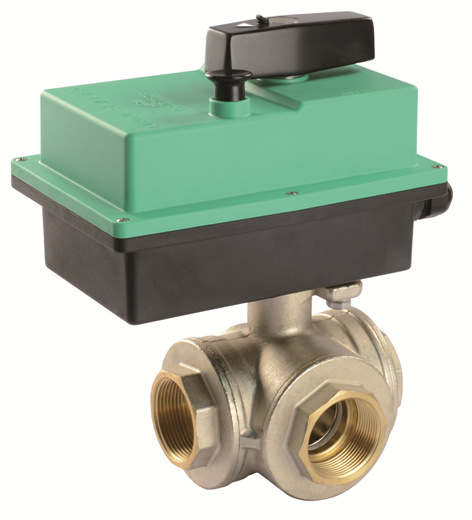

Pulse Solenoid valves are manufactured with single diaphragm or double diaphragm. Solenoid valves with connection sizes such as 3/4″ and 1″ are single diaphragm. Solenoid valves with large connection sizes such as 1 1/2″, 2″ are single diaphragm or double diaphragm. Double diaphragm valves are advantageous in terms of operation compared to single diaphragm valves.

ADVANTAGES OF DOUBLE DIAPHRAGM VALVES:

- Air makes shocking more severe.

- More effective filter cleaning. (approx. 40%)

- Energy is given at longer intervals and shocking is done.

- Diaphragms last longer.

- Energy consumption is reduced by saving compressor air.

As Pulse Solenoid valves are diaphragm valves, they cannot perform the on-off function (even though the coils are energized) without the necessary differential pressure, like other diaphragm solenoid valves. The minimum pressure applied to the inlet should be 0.5 kg/cm2.

When the coil is energized, the armature becomes magnetized and overcomes the spring force and moves upwards, venting the trapped air on the diaphragm through the exhaust. Meanwhile, the compressed air under the diaphragm cannot rise above the diaphragm and regain the pressure balance in a short time. Due to this pressure imbalance, the diaphragm moves up and the valve comes to the open position. This is how shocking happens.

With a double diaphragm solenoid valve, this happens twice. The air on top of the small diaphragm is evacuated first. In this case, the small diaphragm vents the large diaphragm. In this way, differential pressure is created faster and the shock is twice as severe. Shocking takes place by giving energy for 50-120 milliseconds. The shocking interval is set by the operator.

For more information please contact with our sales team on 01234 855888 or via email: sales@v-flowsolutions.co.uk