Manufacturing paraffin wax

M&M Piston actuated valves are suitable for a wide variety of applications. In this blog post, we are going to provide some examples of Piston Valves used in Manufacturing Paraffin Wax and the type of valve that we would recommend for this application.

Piston actuated valves used in manufacturing paraffin wax:

The industrial production of candles uses extrusion machines and presses.

These machines work with paraffin wax powder.

The equipment used for manufacturing paraffin wax powder consists of a leakage tank, a sprinkling unit and a pulverizing roller.

The leakage tank contains solid paraffin wax. The coil heat exchanger warms up to a temperature capable of melting the solid paraffin wax.

Piston Actuated Valve (A) controls diathermic oil at 140° at the pressure of 3 bar and lets it into the tank coil.

Liquefied paraffin pumps through a warm duct and special nozzles sprinkle it onto the cooling roller.

Diathermic oil, controlled by Piston Actuated Valve (B), warms the sprinkling duct.

Scraping the cool paraffin from the roller allows the vibrating ducts to collect it.

The diameter of the cooling roller varies according to the quantity of paraffin to be obtained.

The paraffin wax powder loads into the moulds. Then the moulds press the powder into various shapes to finish the candles.

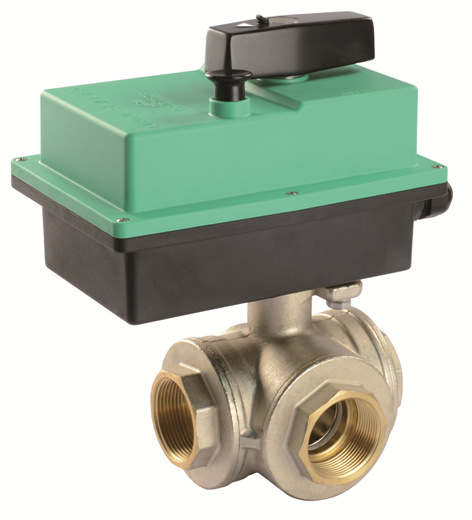

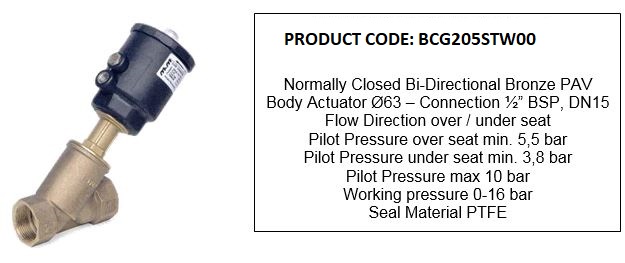

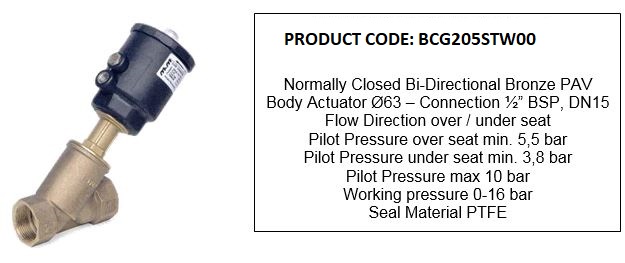

The valve that we would recommend for this application is:

You can view the V-Flow Solutions range of M&M Piston actuated valves here:

V-Flow Solutions: Piston Valves

M&M Angle seat piston valves

M&M piston valves are manufactured in Italy, using the highest quality materials for a high-quality product.

Piston valves use an external control media to pilot the actuator, where a piston connects directly to the main seal that closes onto the main orifice to control the flow of liquids and gases.

V-Flow Solutions highly recommended M&M Piston Valves under these conditions:

• Media containing dirt particles

• Highly viscous media (up to 600 CST (80°E); 1 centistoke = 1 mm2/s)

• High flow volumes

• High temperatures

• Damp environments or hazardous locations

The versions of M&M Piston actuated valves available are:

| | |

| | |

Technical Information

The main seal material used in piston actuated valves:

A modified PTFE has been the main seal material since 2004 when it replaced the original PTFE material seal.

The modified PTFE seal provides these benefits over the previous version:

- Lower porosity and permeability

- Fewer void spaces

- Higher elasticity

- Reduced deformation under load

- Better chemical resistance to controlled media

- Smoother surface and improved design flexibility

The standard bonnet seals consist of 2 ‘V’-shaped FKM gaskets and a package of 25% graphite-filled PTFE gaskets.

High-temperature Piston actuated valves:

M&M can offer a piston valve that can be used up to 200°C, provided that the valve pressure limits are respected.

The main differences, in regard to the materials in this design, are as follows:

- Change of the actuator material: From standard PA6 to PA66 filled with 30% fibreglass

- All valves with DN > 25 with fixed plug design (to withstand turbulence caused by steam at high speed)

- Special design of bonnet chevrons, all are made of 25% graphite-filled PTFE