Solenoid Valves in Vending Machines

Solenoid valves are an important component of drink dispensers and vending machines. Here are some examples of M&M solenoid valves being used in these applications.

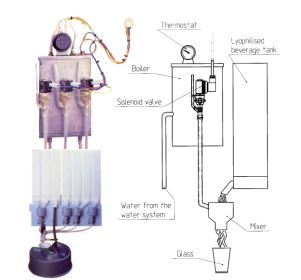

Automatic Hot Drinks Dispenser

Hot drinks dispensers and vending machines are used to distribute coffee, tea and other hot drinks quickly and are usually placed in public areas, work offices or private facilities. The main feature of vending machines consists in a quick distribution of coffee, tea, milk and chocolate.

Vending machines usually consist of two supplying groups, one for coffee and one for soluble beverages.

Application

The sequence of distribution is the following:

First the plastic glass is positioned, then sugar is supplied and finally, the beverage and the coffee spoon are delivered.

When the user selects the product on an electronic push-button panel, the infusion process is activated.

A volumetric dispenser prepares a single-dose of powder into the mixer.

Hot water at a temperature of 90-95°C is delivered from the boiler to the mixer by a vending valve. The level of water inside the boiler is kept constant by an electronic system letting in fresh water from the water supply whenever it is necessary.

Finally, the mixer exploits the centrifugal force to dissolve the powder in water and so obtain the beverage. After the mixing operation, the mixer stops and the beverage falls into the glass due to gravity.

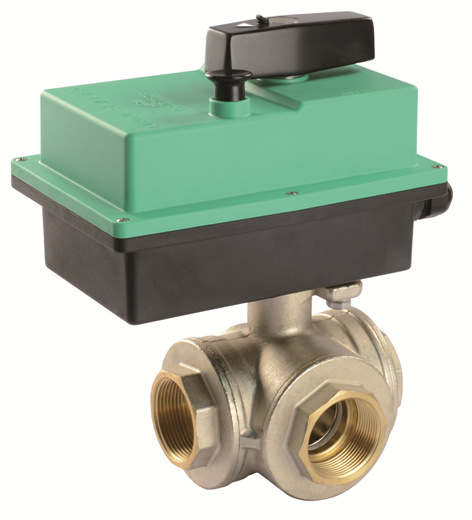

Suitable Valves

Coffee in Cartridge Dispensers

Coffee-in-cartridge dispensers are used to provide coffee and other hot beverages from cartridges, these are usually semi-automatic.

Semi-automatic coffee-in-cartridge dispensers complete with hot water delivery heads are used to supply coffee and soluble beverages in the cartridge.

The hydraulically moved coffee infusion unit automatically expels the cartridge into the specially provided container.

The dispenser can be equipped with a support cabinet with cup dispenser, spoon and sugar drawer and product storage compartment with door.

Small dimensions and easiness of use make them widely used as household appliances but also in shops, offices, associations, laboratories, hotels and wherever a constant supply is not required.

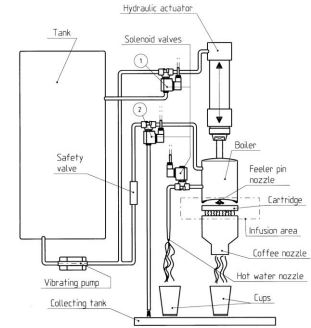

Application

Water contained in a tank is sucked up by a vibrating pump and then intercepted by two three-way solenoid valves.

The former supplies the hydraulic actuator, the latter delivers water to the boiler.

The boiler is always full of hot water whose temperature is adjusted by a thermostat.

It is installed on the actuator stem and is equipped with a pin nozzle that delivers hot water when pressed.

The operation starts when the cartridge is in; the two solenoid valves open at the same time and the actuator pushes the boiler downwards against the cartridge.

A safety valve above the second solenoid valve prevents water from flowing out before the actuator has descended completely.

When the pressure of 9-10 bar has been reached inside the circuit (about 10 sec.), the safety valve opens, cold water flows into the boiler while water that had previously been warmed up flows out and filters through the cartridge.

The mixture produced (coffee, tea, chocolate, cappuccino, etc.) flows through a nozzle into the cup.

At the end of the cycle, the second solenoid valve closes and exhausts the remaining hot water under over-pressure from the third way into the collecting tank.

Then the first solenoid valve closes and water under pressure inside the actuator is exhausted from the third way into the tank. The actuator returns into its rest position under the effect of the spring.

When a different control is selected, only hot water is delivered. A two-way solenoid valve connected directly to the boiler intercepts hot water and pours it directly into the cup through a different nozzle.

Suitable Valves

For more information or to speak to a member of our technical team, please contact us on;

Telephone: 01234 855888

Email: sales@v-flowsolutions.co.uk

Alternatively you can use the contact form below.