Stainless Steel Solenoid Valves

For applications where the media is not compatible with brass a stainless steel bodied solenoid valve may be more suitable. Stainless steel solenoid valves are ideal for use in certain aggressive media and chemical applications.

Valve bodies are generally made from stainless steel grade 1.4305 EN 10088/AISI 303 or ASME SA351/351M AISI316L CF3M.

To further improve suitability with aggressive media the shading ring is generally produced from silver as opposed to the more commonly used copper. Silver has a better resistance to the effects of harsh acids and alkali.

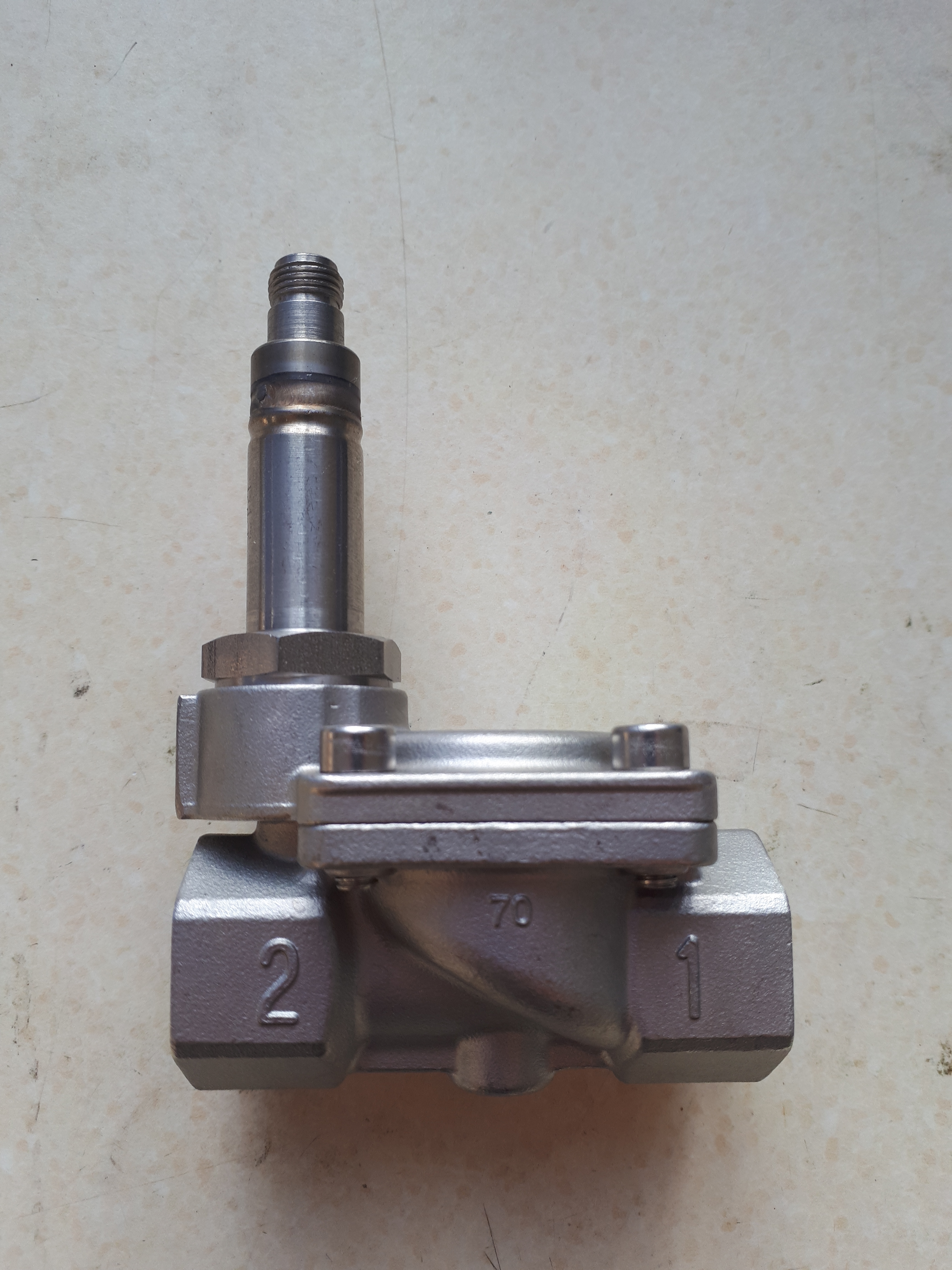

Seamless armature tubes (no welded parts) offer further protection against the effects of aggressive media. A standard armature tube is welded at the base of the tube. Welded parts are more likely to be affected by the corrosion that can be caused by the use of harsher media.

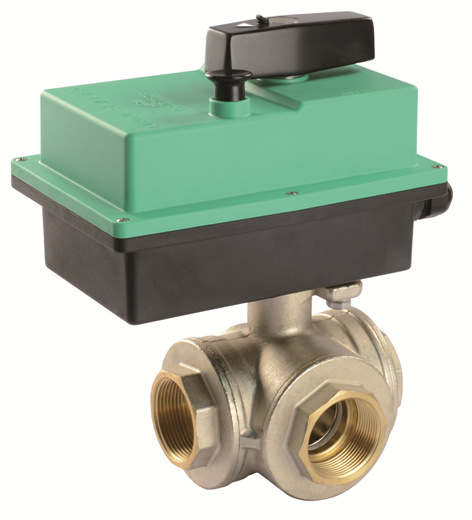

An example of a stainless steel solenoid valve (left) and a seamless armature tube (right).

Example Stainless Steel Solenoid Valves

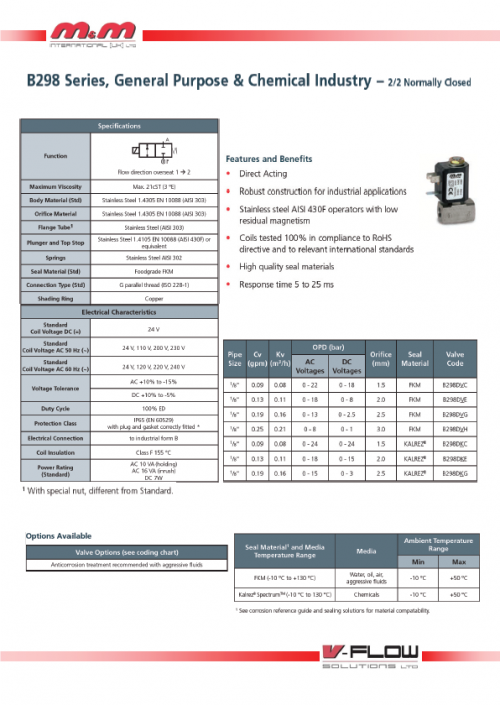

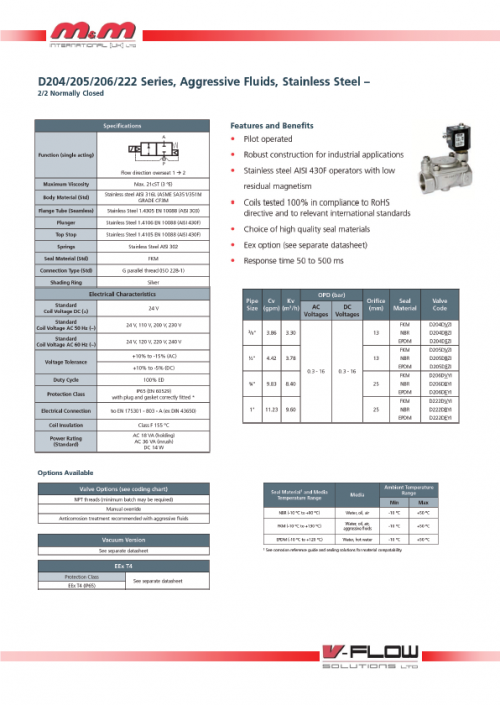

Below are example specification sheets for V-Flow Solutions stainless steel solenoid valves:

For chemical applications

For applications with aggressive fluid

You can view the V-Flow Solution range of solenoid valves here:

The Basic Principles of a Solenoid Valve

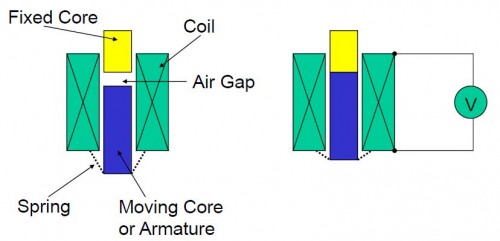

The principal of a solenoid valve uses a copper wound coil over an armature housing a fixed core and a moving core. When the coil electrically energises the moving core attracts to the fixed core.

When the coil energises, the armature attracts to the fixed core, the spring compresses and the valve opens allowing flow. Lifting the armature to the fixed core consumes more power than holding the armature, this is referred to as the inrush and holding power. The inrush is the power required to lift the armature and the holding is the power required to hold the armature in place.

Available Features (Optional)

We can supply Normally closed direct acting and pilot operated solenoid valves with a manual override which allows the valves to be opened independently of electrical current.

How this works:

There is a small CAM in the valve, below the armature. Rotating the CAM lifts the armature. As a result of this, the valve opens.

Pilot operated solenoid valves can be supplied with a system that has the ability to regulate the closing speed of the diaphragm in order to control waterhammer.

(An increase in flow pressure through a previously empty valve is the cause of waterhammer).

The anti waterhammer device is a needle valve built into the valve body. By rotating the needle valve clockwise the needle valve restricts the orifice reducing the flow rate, thus slowing the closing speed of the diaphragm.

The Benefits of M&M International Solenoid Valves

High reliability

Long life

Corrosion resistant

High performance

High compatibility with a wide range of media

High flexibility with reduced stock

Simple and quick installation

Customer tailored solutions

For any other products, including Solenoid valves, Actuators, Actuated valves, Manual valves and much more, please take a look on our website:

If you think V-Flow can help you then please contact us:

Telephone: 01234 855888

Email: sales@v-flowsolutions.co.uk

Alternatively you can use the contact form below.

V-Flow are the experts of flow control.

If you have a problem with flow control, we will find the solution.