M&M Piston Valves

M&M Piston actuated valves are suitable for a wide variety of applications. In this blog post, we are going to provide some examples of piston valves in metal cleaning machines applications. We also recommend a valve for the application.

Piston Actuated Valves In Metal Cleaning Machines

Metal cleaning machines are industrial cleaning machines with a closed-circuit drying system.

They clean metallic parts of iron, aluminium, brass, bronze, stainless steel, etc. using solvents (ex. Perchloroethylene) and dry them with hot air.

The cleaning operation contains three stages:

A) With hot solvent;

B) With cold solvent;

C) With solvent fumes.

The three stages are independent and repeatable, and their duration is adjustable dependant on the type of material to be de-greased. The cycle ends with the complete drying of the material. Constant distillation keeps the solvent clean.

Components that need cleaning, should be put inside the drum where the solvent circulates (according to the cleaning cycle, hot, cold or fumes clean the components).

Dirt deposits on the bottom of the drum and a special filter collects it. A distiller gathers the condensation and the fumes from inside the drum after the removal of impurities (slag, air, water, oil, etc.).

The clean solvent then resumes its process in the cleaning cycle. According to the cycle, the solvent can be warmed up by a steam jet at 140° generated by a specially provided boiler and controlled by the valve (A).

The solvent conveys into the drum. For the drying operation, before we reintroduce air into the drum, we remove it from the drum, depurate and warm it.

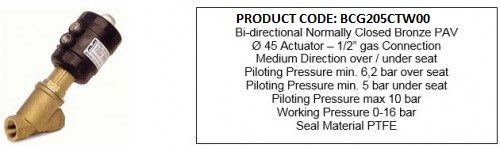

The type of valve we recommend for this application is:

You can view the full range of M&M International Piston valves here.

To return to the home page click here V-Flow Solutions.

You May Also Like

Piston Valve Applications: Manufacturing Paraffin Wax

Piston Valve Applications: Casting Systems